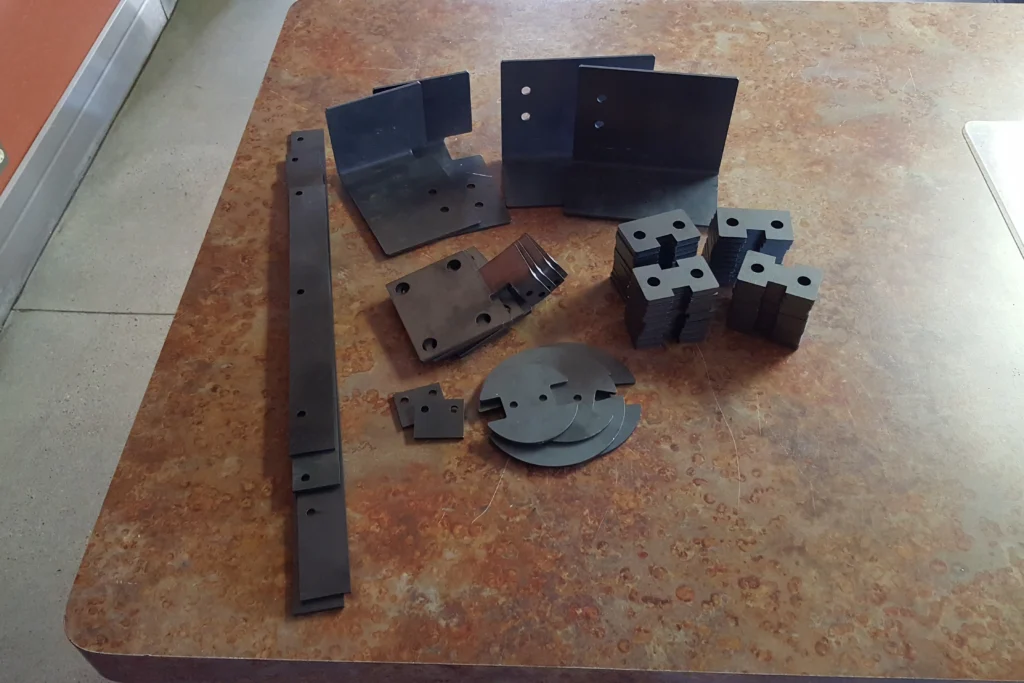

S&R Sheet Metal is a leading provider of high-precision metal laser cutting. Our team S&R Sheet Metal is a leading provider of high-precision precision laser cutting services. Our team of skilled trade workers blends cutting-edge CNC technology with old-fashioned craftsmanship and customer service. With metal laser cutting and plasma-cutting services, the opportunities are endless.

Call us today to learn more about our metal laser-cutting capabilities. View some of our past work here!

In metal fabrication, there are several methods we regularly use to cut and shape metal. However, laser or plasma cutting is one of the best techniques – especially if you are making duplicates or require a high level of accuracy. Some of the biggest advantages of metal precision laser cutting services include:

When it comes to laser precision, cutting-edge technology makes the difference. To ensure we can provide you with the highest level of quality and accuracy, we have two pieces of advanced equipment that we use on metal laser cutting projects:

These options allow us to cut precision parts and components that perfectly suit our clients’ needs. Our laser can cut up to 1″ thick material.

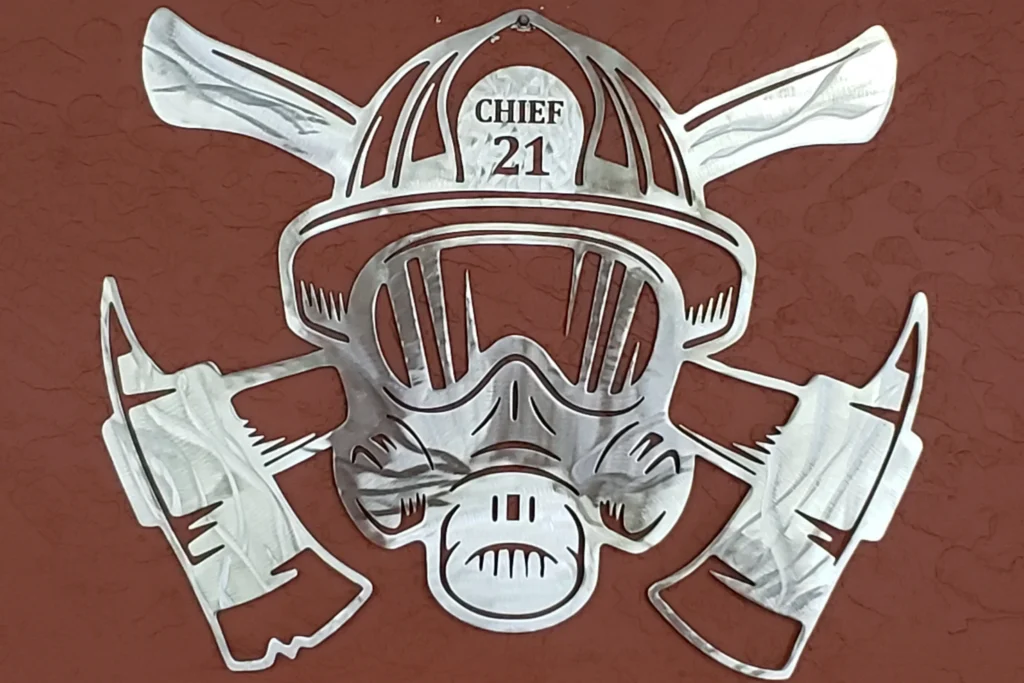

Whether you need a high volume of accurately-cut metal products or a custom-designed metal piece, we have the capability to create it for you.

Check out our gallery to see more examples of the laser cutting work we’ve done.

Our laser-cutting process revolves around you and your goals. Once the design is complete and approved, we nest the drawing into our laser or plasma cutter’s internalized computer system. After adjusting the appropriate settings, we begin the “burning” process.

No matter what type of metal product you need, S&R Sheet Metal is here to help. With over 40 years of experience providing a wide range of laser cutting and metal fabrication services, our highly skilled team is prepared to bring your vision to reality. Our team is ready to help. Enjoy short turnaround times, excellent customer service, and quality results with our team – call us today to get started!