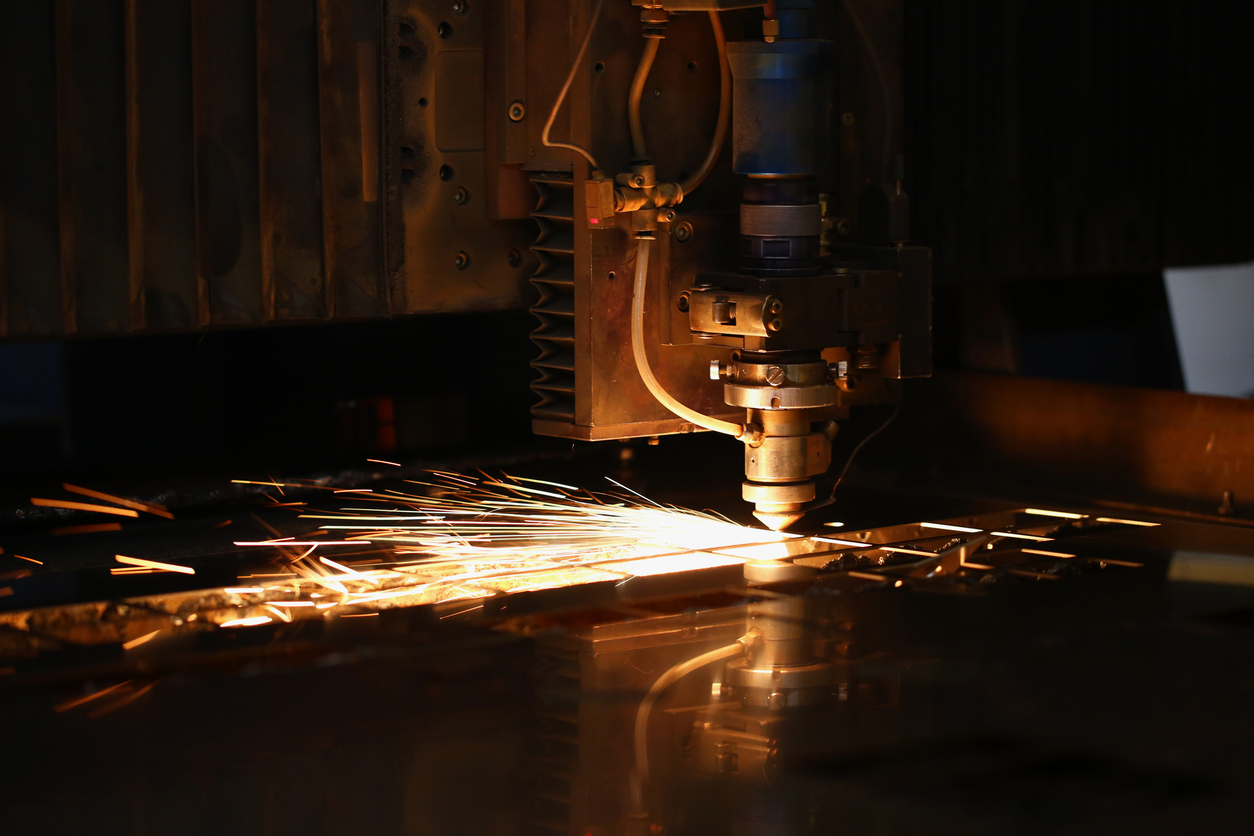

The manufacturing industry moves fast, and you need quality metal-cutting services that can help you stay ahead of the competition. Laser cutting has emerged as one of the fastest, most energy-efficient, and cost-effective ways to process metal into a final product. Fiber lasers, specifically, can help all businesses reduce costs and get to market faster.

Whether you’re a small workshop needing intricate designs or a large manufacturer looking to optimize production, understanding the ins and outs of laser cutting can significantly enhance your project outcomes. In this guide, we’re answering some common questions about laser cutting to help you make an informed decision for your business.

Commonly Asked Questions About Laser Cutting Services

What type of laser-cutting machinery is there?

There are quite a few different types of laser-cutting machines — the most common being fiber lasers. These lasers only cut metal like aluminum, steel, and brass. They’re well-known for high speed and efficiency.

How does laser cutting compare to plasma cutting?

There is no real comparison between laser cutting and plasma cutting. While they are both used to process metals, laser cutting always comes out on top. Lasers cost less to operate, are faster, and create a cleaner cut. If you’re looking for quality cuts quickly, a laser will be the best option.

Is laser cutting suitable for small and large production runs?

Today’s lasers can easily handle both small and large production runs.

What design considerations do I need to keep in mind for laser-cutting projects?

Designing a part for laser cutting is crucial, as there are some designs that may be difficult to achieve. Parts must be designed with open contours, kerf compensation, and bridging. You must also ensure that your internal geometry isn’t too small and leaves space for the laser’s diameter.

How cost-effective is laser cutting?

The initial investment in laser cutting can be large when compared to waterjet or plasma cutters. However, lasers do cost less to operate and are faster than waterjet and plasma. Additionally, you’ll achieve better cut quality with laser, which can reduce secondary operations.

What industries commonly use laser cutting services?

Lasers are commonly used in the automotive, construction, electronic, medical, military, aerospace, and metalworking sectors, among others. Their speed and accuracy ensure quality cuts, every time. This makes laser an extremely attractive option when looking at different metal processing methods.

Are there limitations to the thickness of materials that can be cut?

Fiber lasers can typically cut up to one-inch thick carbon steel, stainless steel, and aluminum. They can cut ⅛-inch thick copper and bronze, and 3/16-inch thick brass.

Work with S&R Sheet Metal for Your Laser Cutting Needs

If you’re looking for quality laser cutting services, turn to the S&R Sheet Metal team. Since 1974, we’ve been delivering high-quality fabrication solutions from our facility in Kelso, Washington. Our services cover architectural, industrial, and contract fabrication, along with metal laser cutting. We even provide installation services across the Pacific Northwest.

As a team of skilled trade workers, we believe our mission has two parts. The first is to provide outstanding sheet metal fabrication services to our customers in a wide variety of industries. The second is to treat our people well. We’ve been part of the community for 50 years and are committed to providing economic opportunity, safe working conditions, and consideration for every human involved in our business activities.

When you work with us, you can expect over 50 years of local industry experience, expertise from highly skilled trade workers, short turnaround times, excellent support, and superior quality products.

Let’s Get Started

Ready to learn more about what we can do for you? Reach out to our team to get started.